Greeting

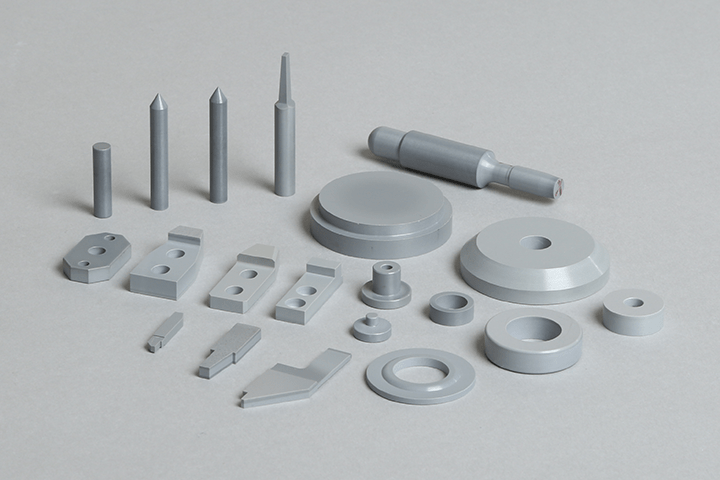

We have been as advantages than other companies to be integrated production since established in1959,from the raw material processing to sintering. We are challenged to constantly reseach and development in order to respond to the diversification of the market changes and customer need. We are producing with all technology that has been developed 60years,responds to the need of a wide range of users.

- Company name

- Ohtsuka Ceramics Inc.

- Location

- ■Head Office&Factory

482-1 Han-ya Shimotsuma Ibaraki JAPAN

■Tokyo Office

3-2-16 Sugamo Toshima Tokyo JAPAN - Establishment date

- 23.Oct.1959

- President

- Kiichiro Ohtsuka

- Capital

- JPY 16,337,500

- Customer

- Automotive parts,Electrical and electronic components,Semiconductor components and mecanical parts industry

- Manufacturing materials

- Alumina,Steatite,Zirconia,Forsterite,Cordierite,Silicon Carbide,Silicon Nitride,and more

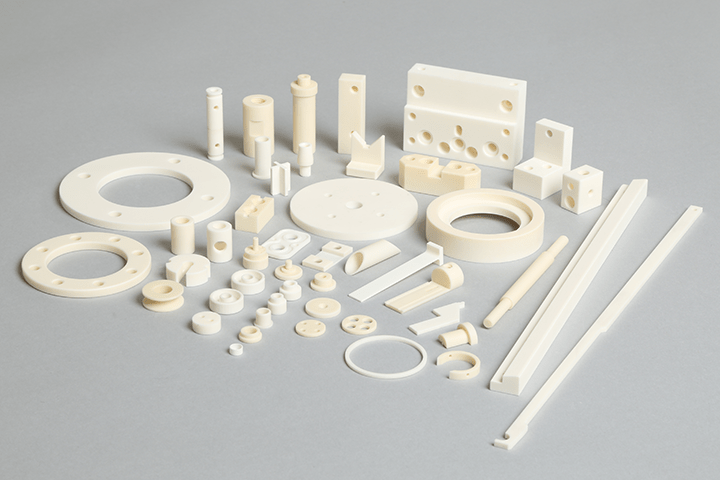

- Alumina

- This is used in the various fields requiring mechanical strength,electrical resistance properties,a heat resistance,wear resistance and chemical resistance.

- Steatite

- This is excellent in mechanical strength and electrical insulation properties compared to porcelain,also a high-precision parts can be mass-produced at comparatively low cost by the mold. And also green body has a good machinability,its can be a small amount produced by machining.

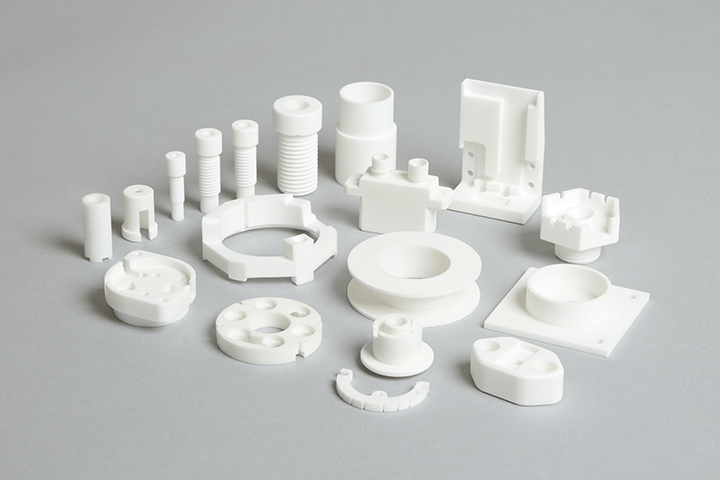

- Zirconia

- This is most in toughness and mechanical strength at room temperature,therefore has been used for a parts requiring wear resistance and shock resistance.

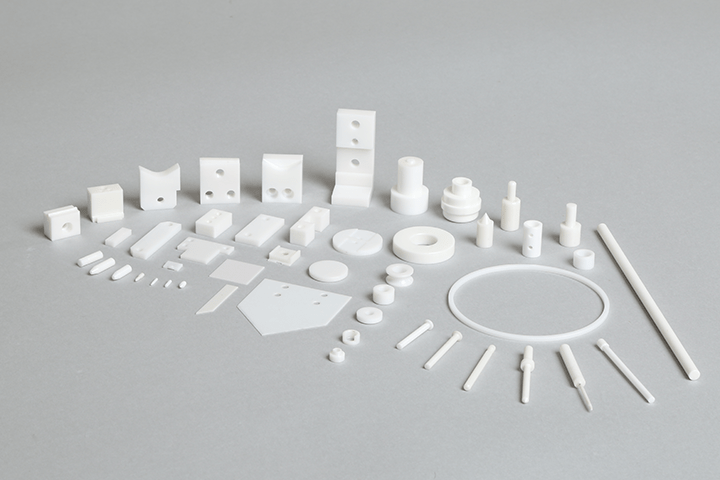

- Cordierite

- This is a ceramic with a very small coefficient of thermal expansion.

Its value is about half that of alumina etc.Hard to get damaged by thermal shock.

It is also used in automotive catalysts and fuse cases.

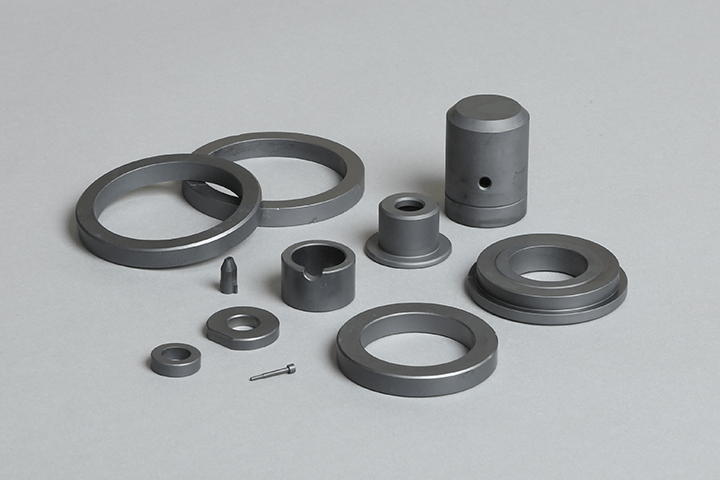

- Silicon Carbide

- This is used for sliding parts such as mechanical seal because of its excellent hardness,thermal conductivity,high temperature and corrosion resistance.

- Silicon Nitride

- This is a non-oxide ceramics versatile with a very excellent characteristics. This ceramics can used in harsh environments because of its excellent high-strength,high toughness,excellent corrosion resistance and wear resistance.